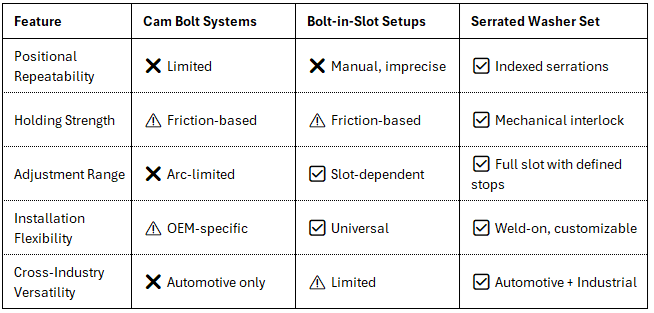

✅ Why It Outperforms Cam Bolts and Slot Bolts

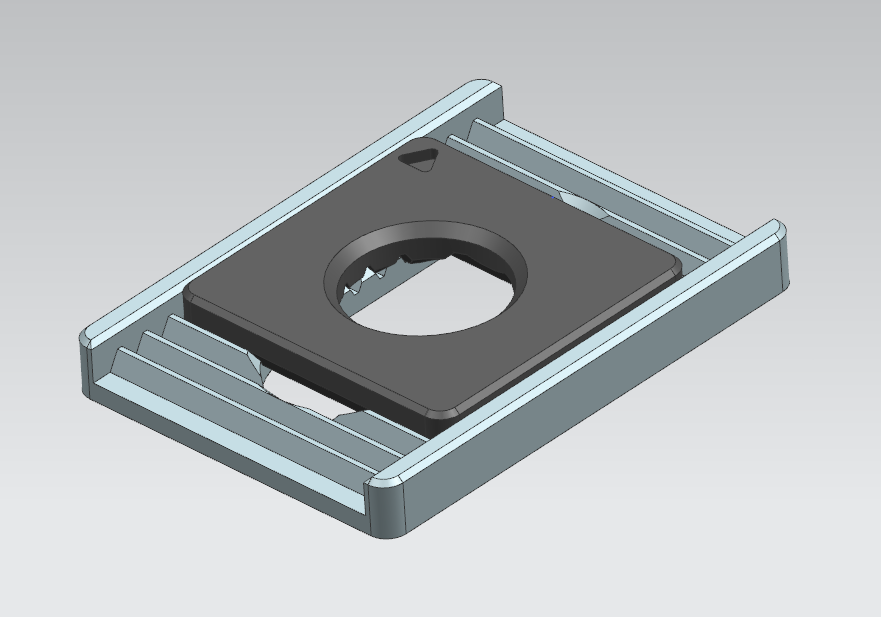

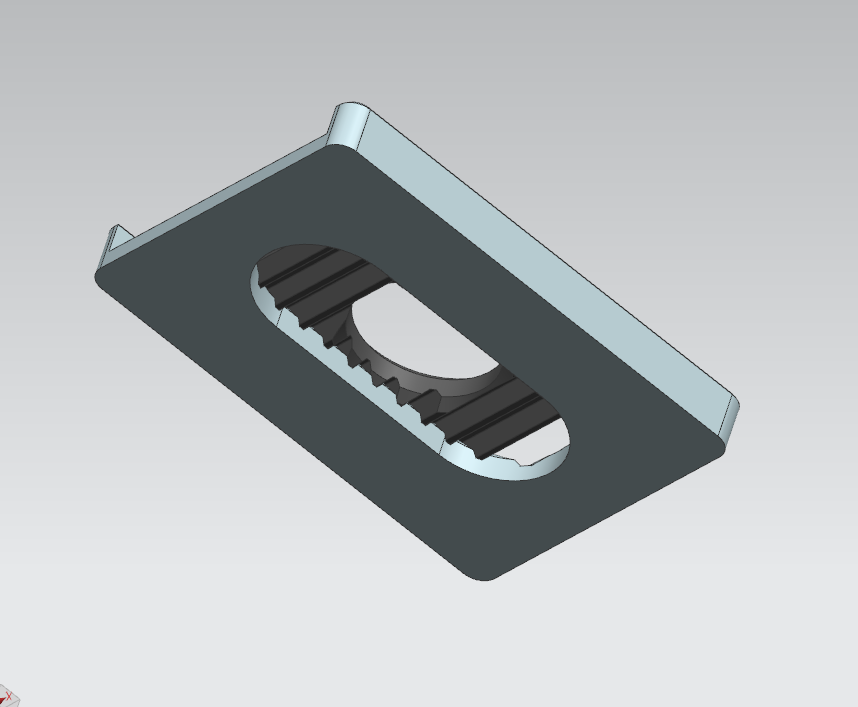

Defined Positional Control: Serrated teeth provide indexed adjustment points, ensuring consistent alignment every time.

Superior Retention Strength: Unlike cam bolts or friction-based slot bolts, this system resists movement from vibration, torque, or impact.

Wider Adjustment Range: The slotted base allows for greater travel than the limited arc of cam-style adjusters.

Permanent Integration: Weld-on design makes it ideal for custom setups, race applications, and structural assemblies.

Simplified Realignment: Once installed, adjustments are intuitive and tool-efficient—no recalibration or guesswork required.

Why Settle for Friction When You Can Lock with Confidence?

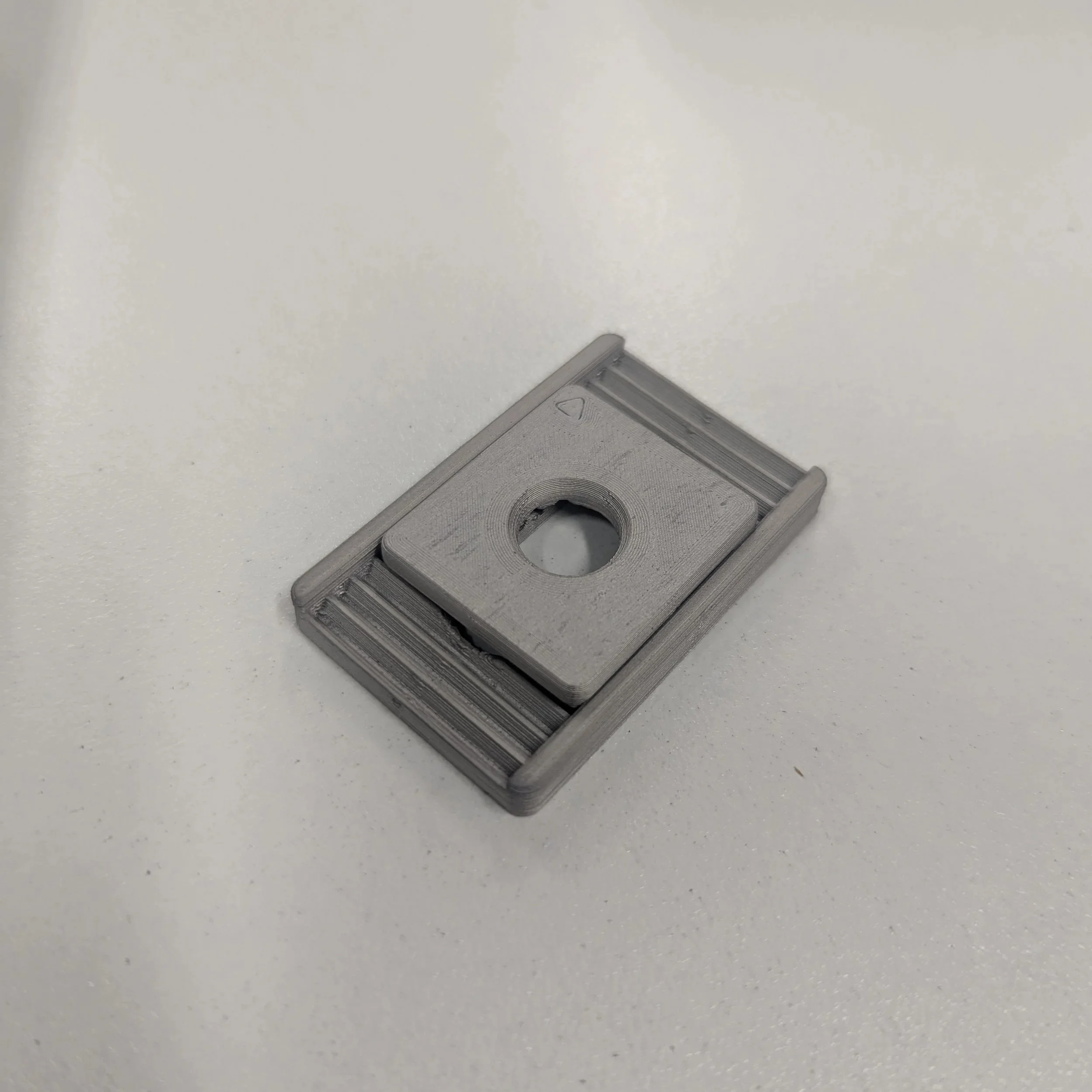

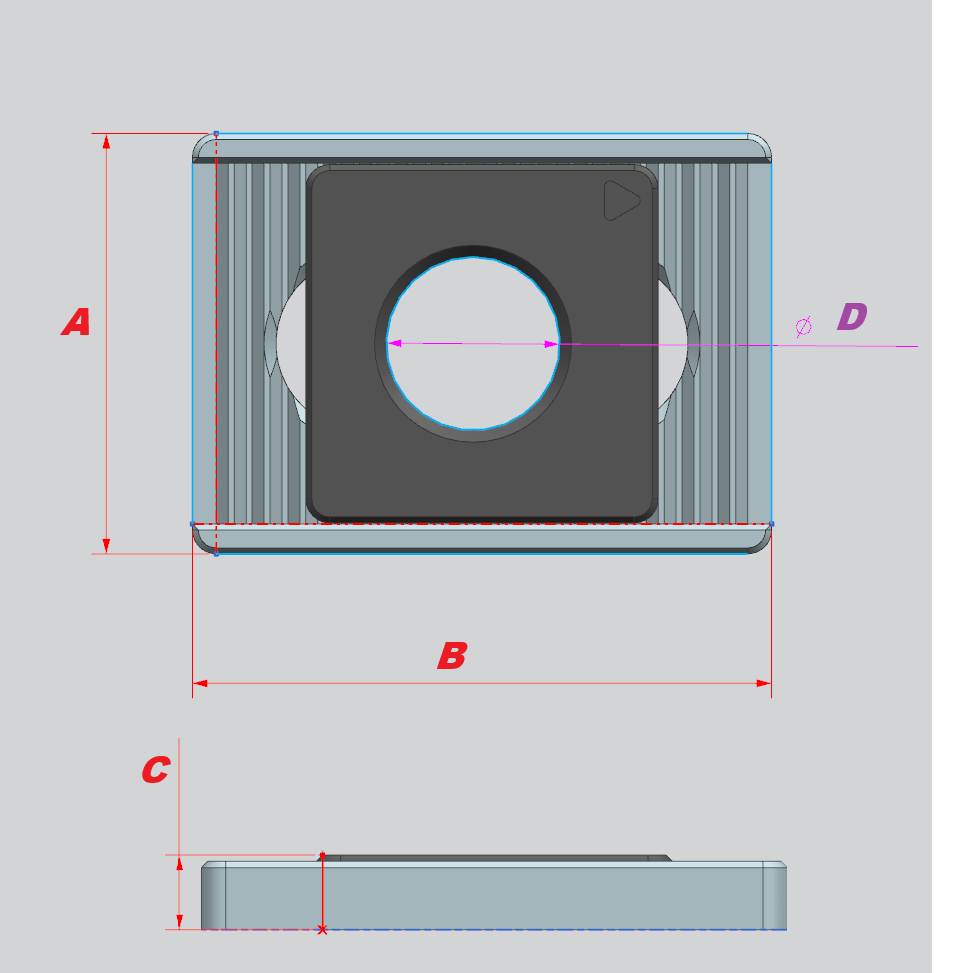

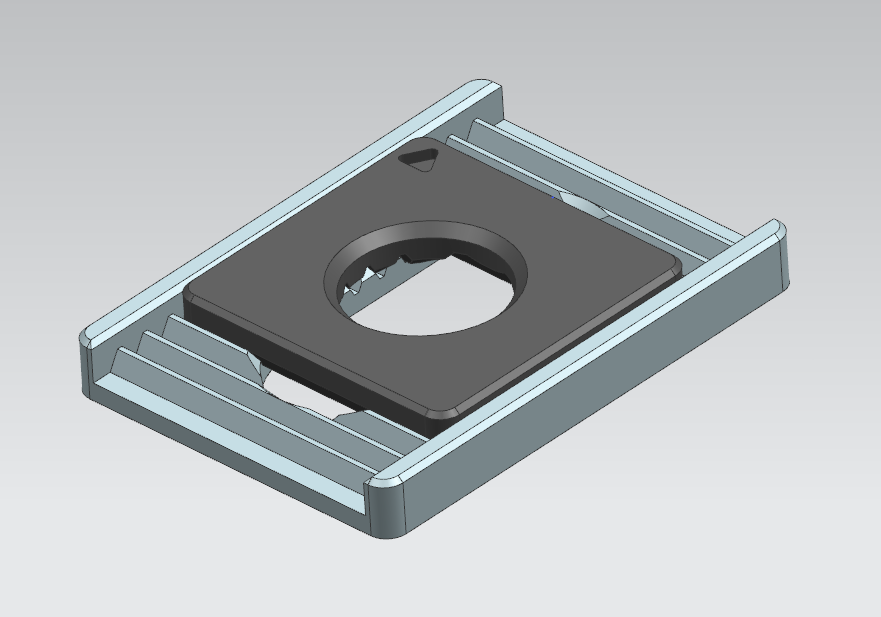

Cam bolts rely on friction. Bolt-in-slot setups rely on hope. Our serrated washer system replaces both with defined mechanical engagement. The slotted washer welds directly to your component, while the holed washer interfaces via precision-cut serrations — giving you indexed, repeatable positions that hold firm under torque, vibration, and load.

🔍 Key Differentiator

🌐 Built for Automotive. Ready for More.

While this system was born from the need for better vehicle alignment — especially in performance, off-road, and custom fabrication contexts — its design is universally applicable. Any scenario requiring adjustability with rigidity benefits from this solution:

Industrial machinery: Lock down adjustable brackets or fixtures with confidence.

Robotics: Maintain precise sensor or actuator alignment across maintenance cycles.

Fabrication jigs: Enable repeatable setups without recalibration.

Modular assemblies: Allow for field adjustment without compromising structural integrity.

🛠️ Use Cases That Sell Themselves

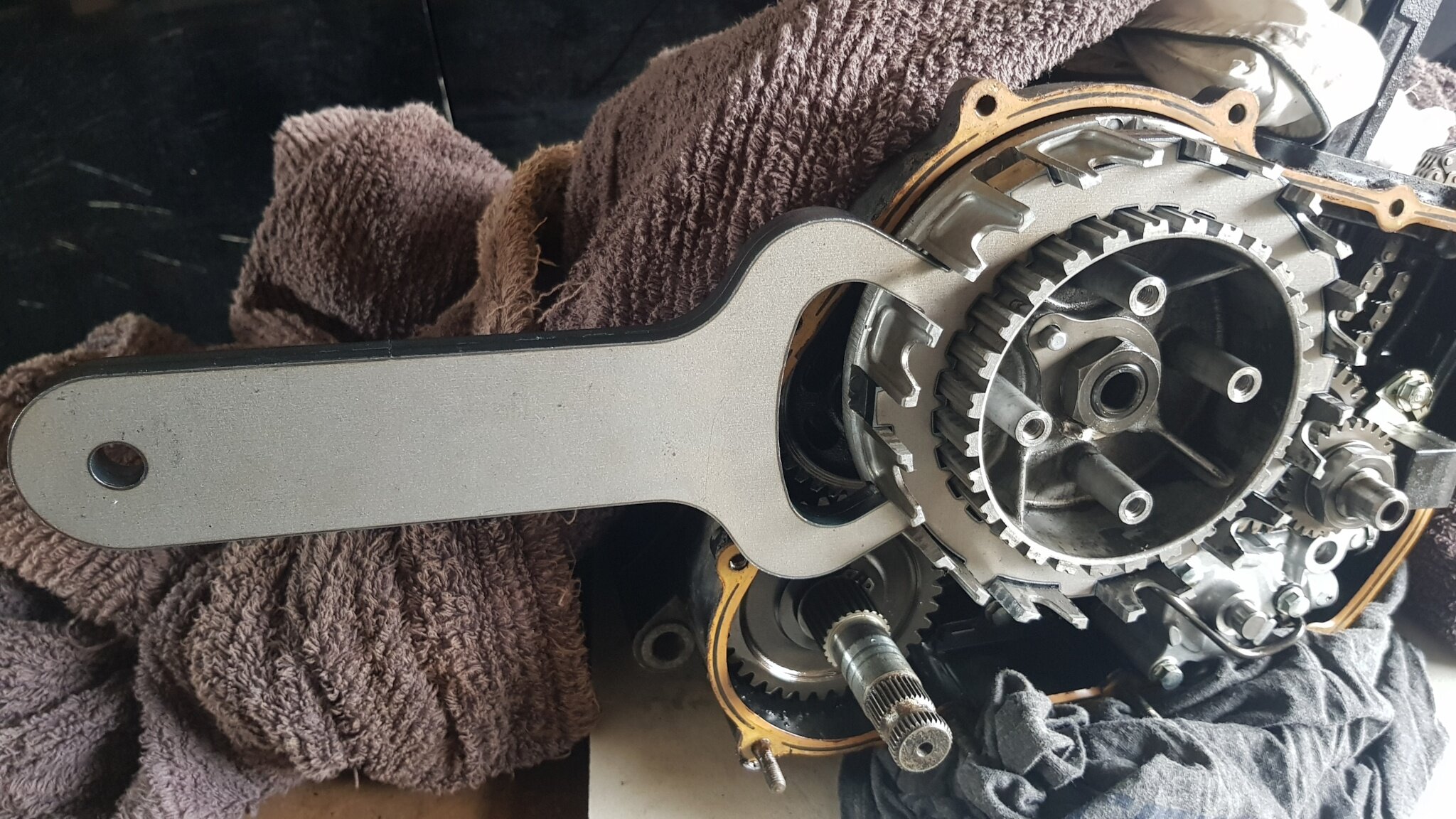

• Suspension tuning with repeatable camber/caster settings

• Axle or subframe alignment in custom builds

• Adjustable mounts for sensors, brackets, or panels

• Structural setups requiring field-adjustable rigidity

• High-vibration environments requiring secure mechanical indexing

• Tight packaging zones where traditional adjusters won’t fit

🔩Made from Solid 17-4PH Stainless Steel

Built for environments where strength, precision, and corrosion resistance are non-negotiable, this serrated washer set is machined from solid 17-4PH precipitation-hardened stainless steel — a material trusted across aerospace, motorsport, and industrial sectors. Known for its exceptional mechanical strength, dimensional stability, and resistance to fatigue and corrosion, 17-4PH ensures this alignment system performs reliably under high torque, vibration, and environmental stress.

Tensile Strength: 700Mpa

Hardness: Up to HRC 44

Corrosion Resistance: Comparable to 304 stainless, with superior strength

Dimensional Stability: Excellent for precision alignment applications

Weldability: Suitable for structural integration with proper technique

🛠️ Sizing

🛠️ Need a different fit? We’ve got you.

Our alignment sets aren’t just off-the-shelf — they’re adaptable. Whether you're working with oversized slots, non-standard holes, or something in between, we can tailor the design to suit your exact specs. If you don’t see the size you need, reach out. We’re always open to custom requests and happy to explore what’s possible.

🚚 Delivery

All items are manufactured on-site at our advanced additive manufacturing facility in Melbourne, Australia.

Production is currently made to order, with a lead time of approximately 2 weeks for manufacturing, plus shipping.

All orders are shipped via Australia Post.

🤝 Wholesale & Distribution

Are you a wholesaler or distributor interested in stocking this part?

We offer distribution agreements, bulk purchasing options, and volume discounts.

Please contact us to discuss tailored arrangements.