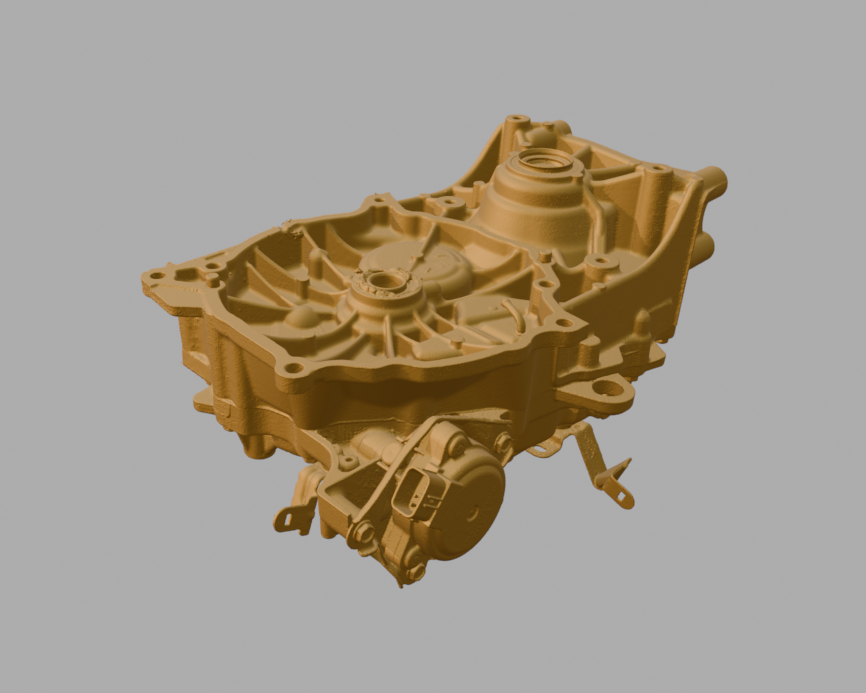

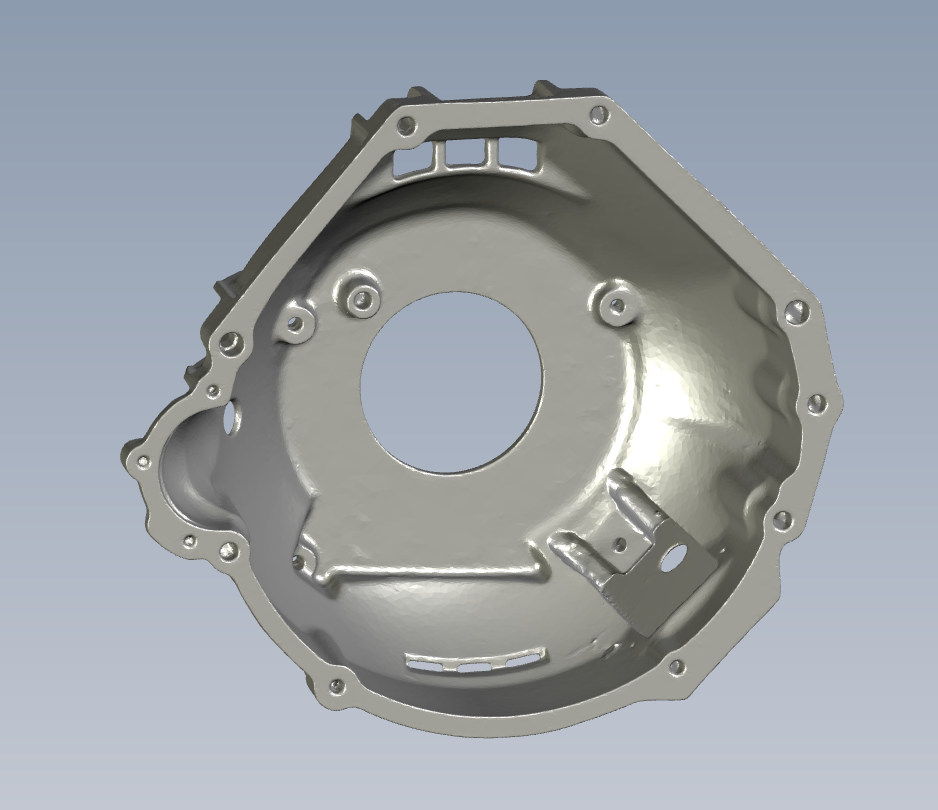

Image 1 of 5

Image 1 of 5

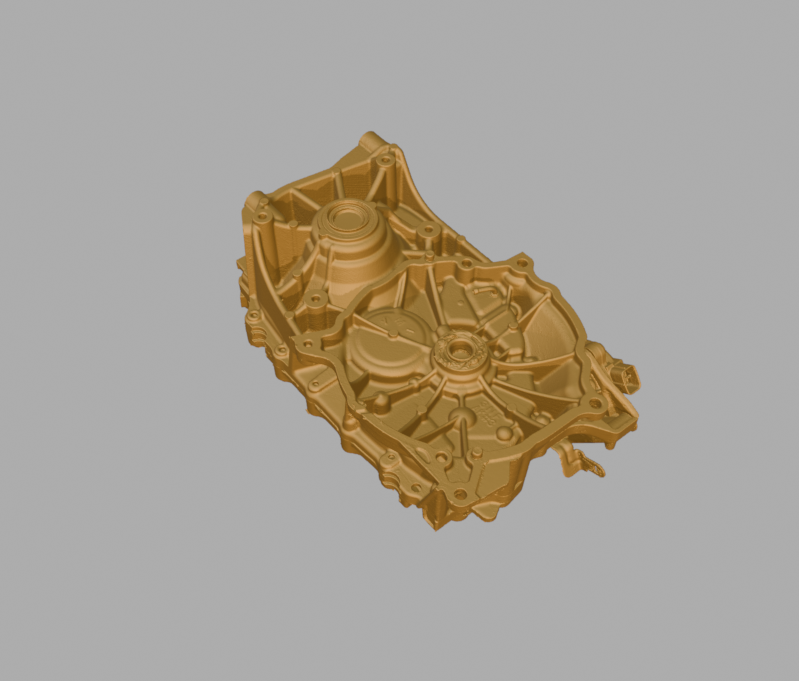

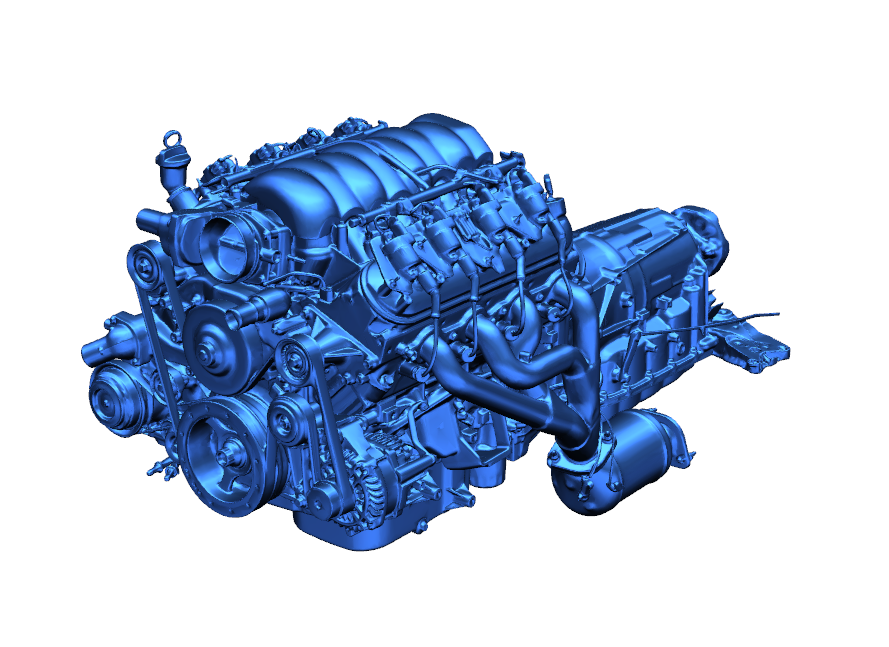

Image 2 of 5

Image 2 of 5

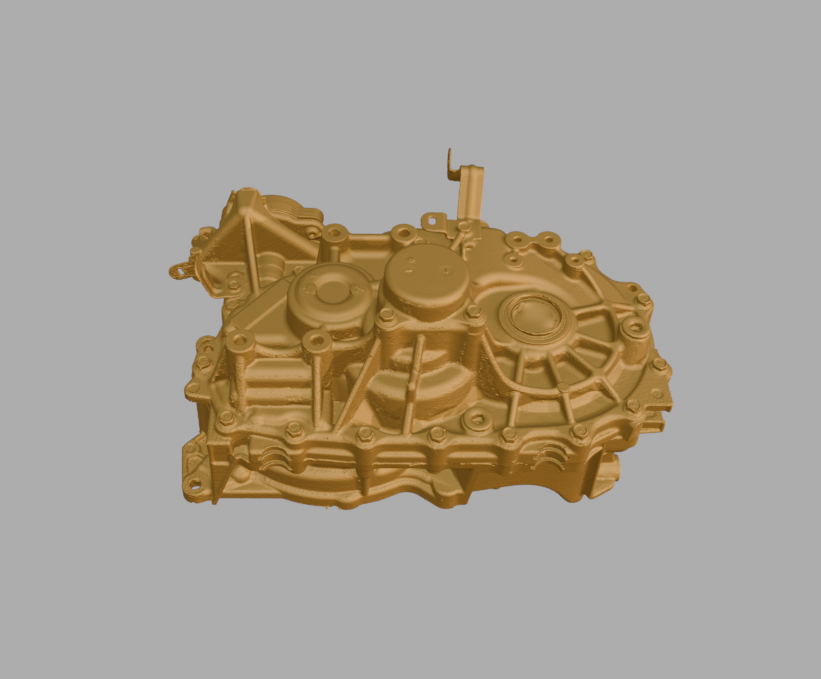

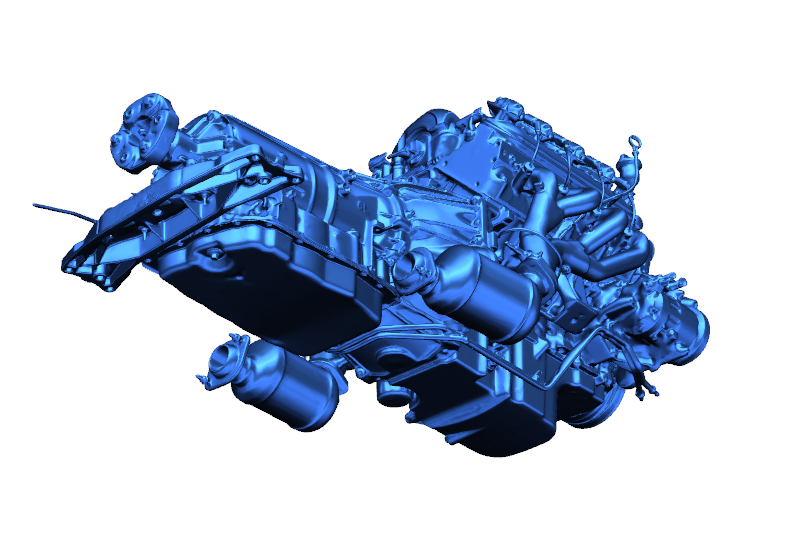

Image 3 of 5

Image 3 of 5

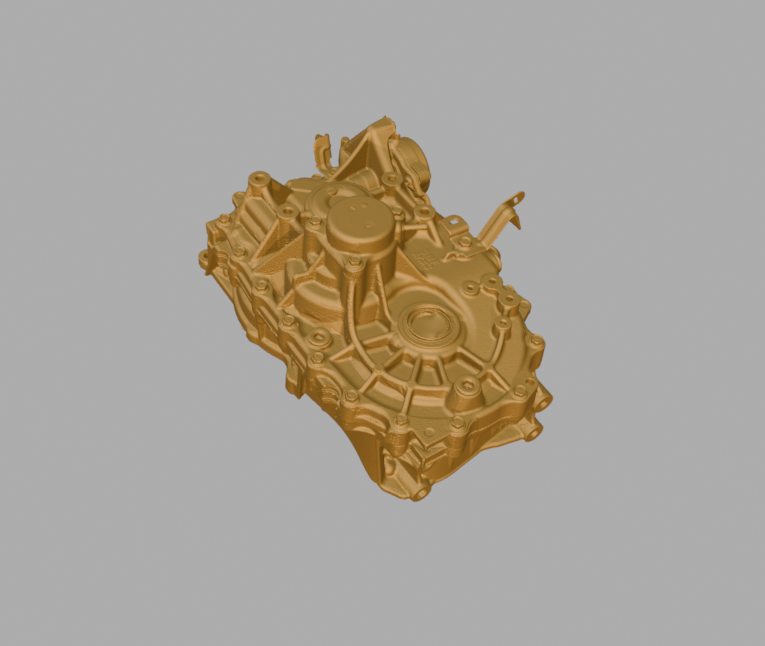

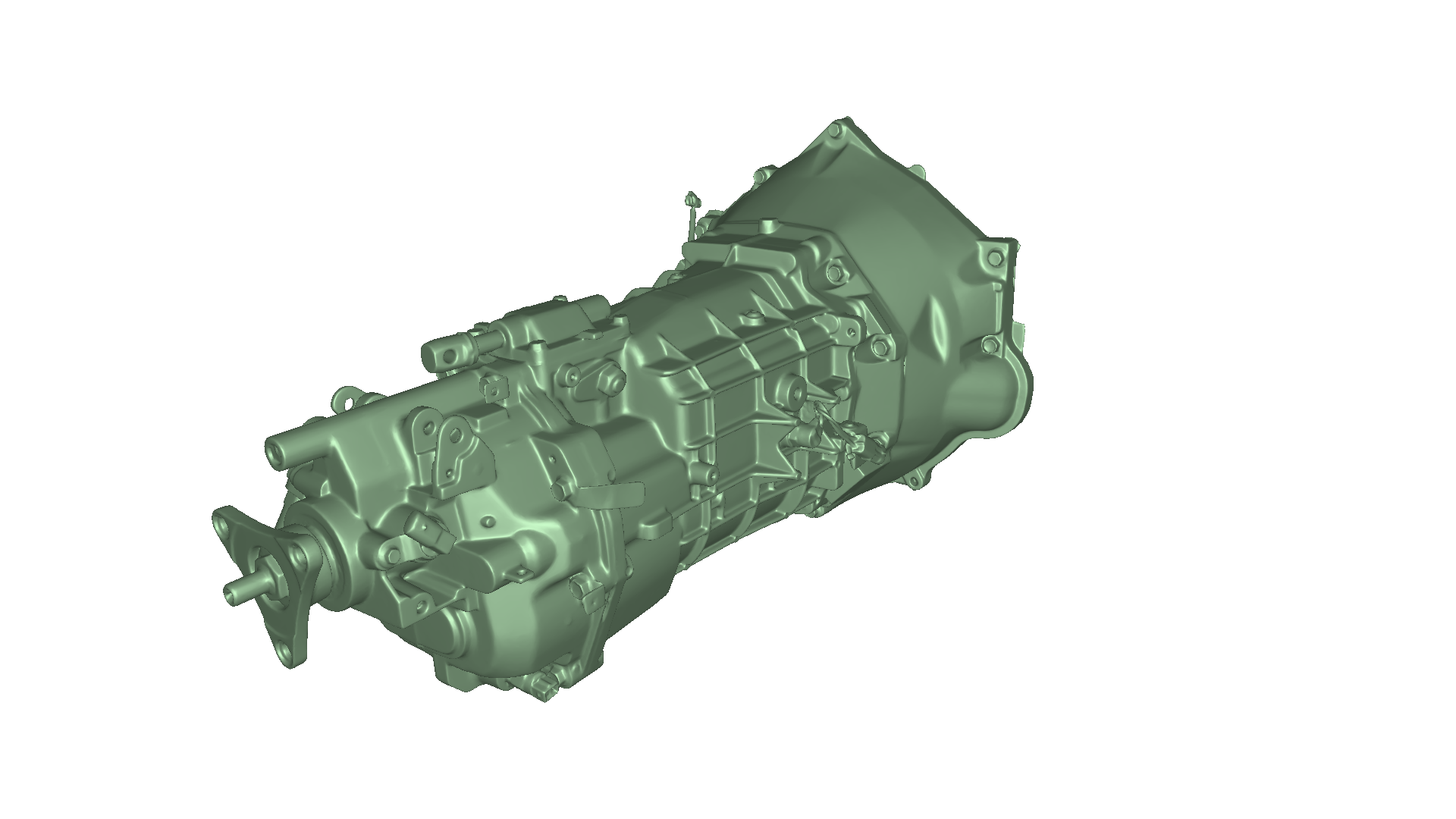

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

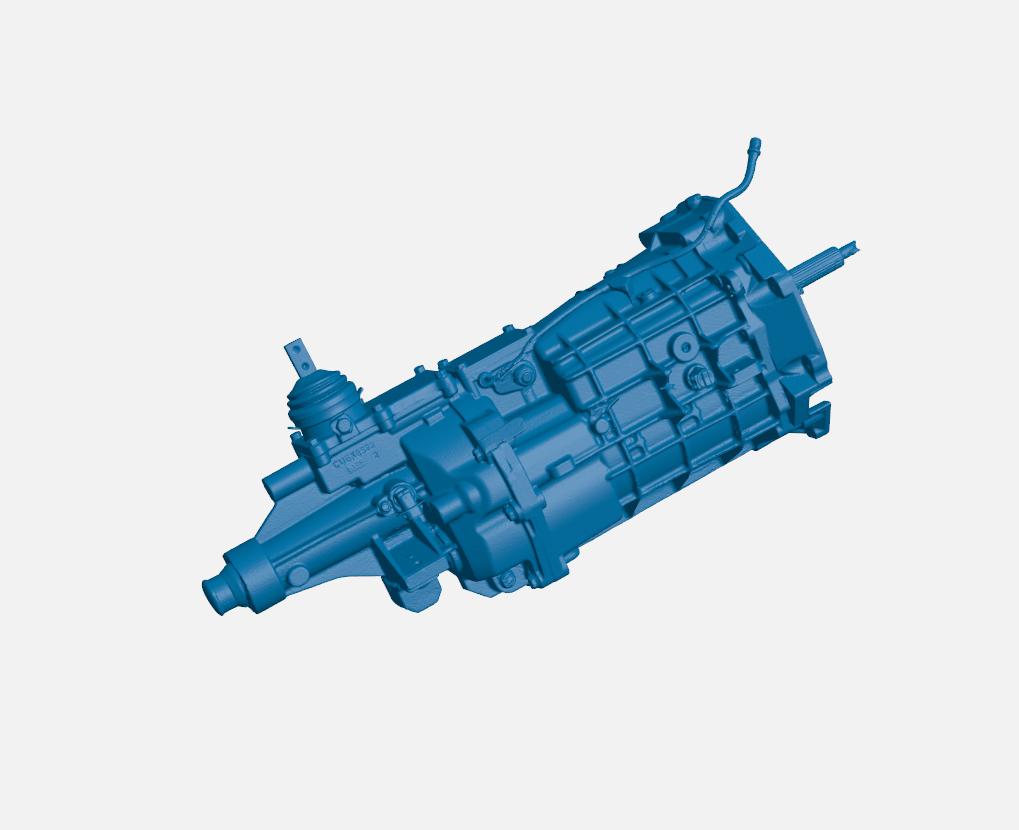

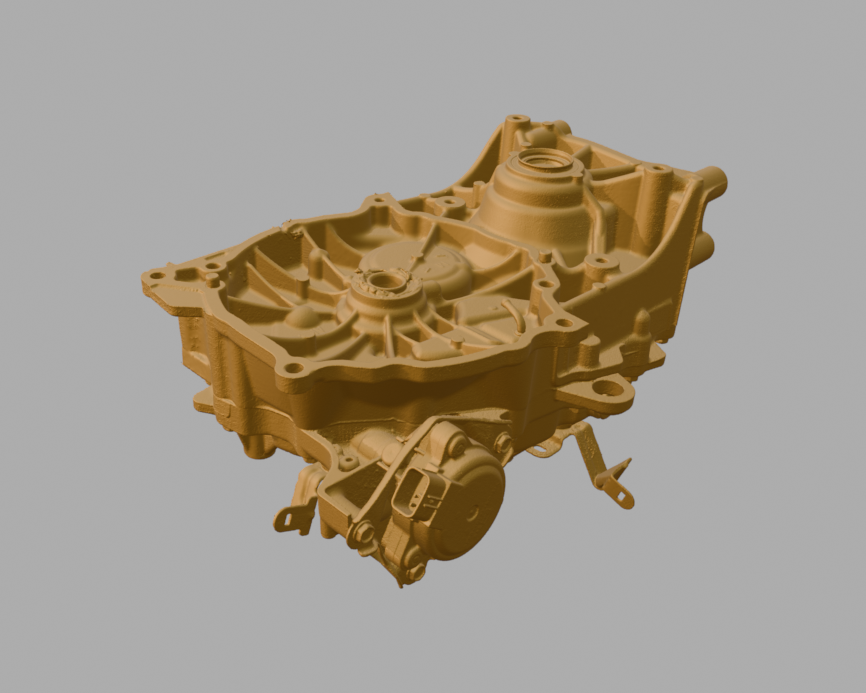

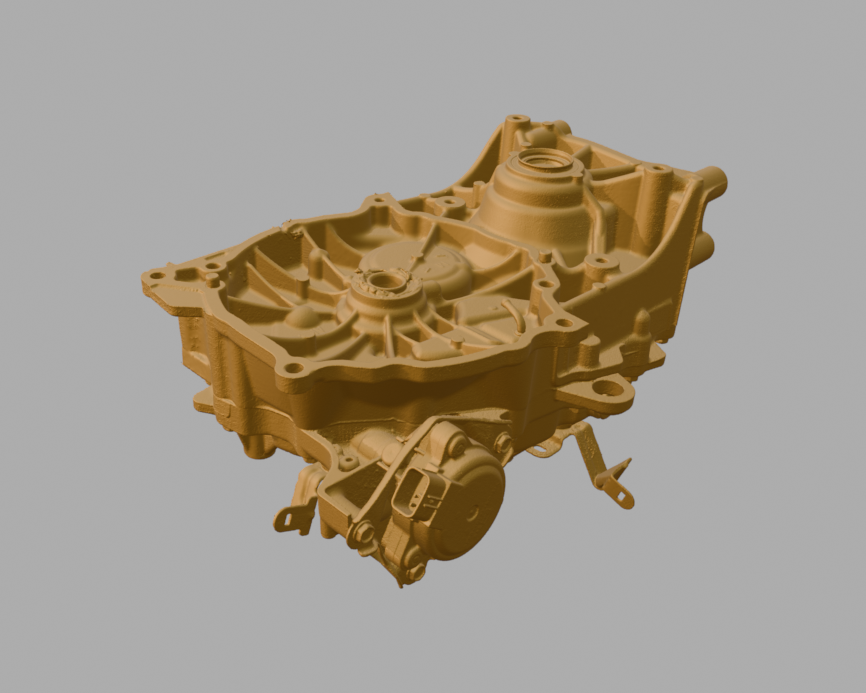

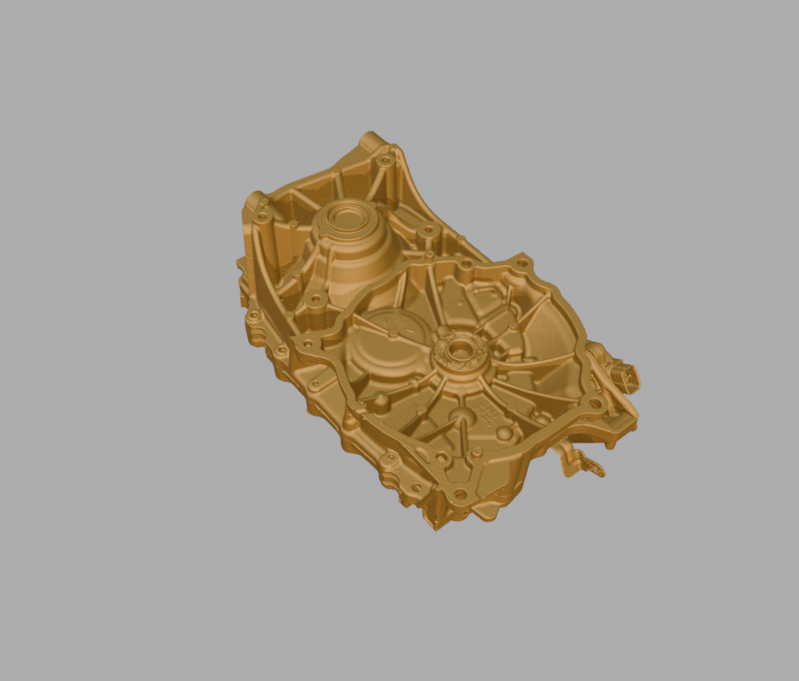

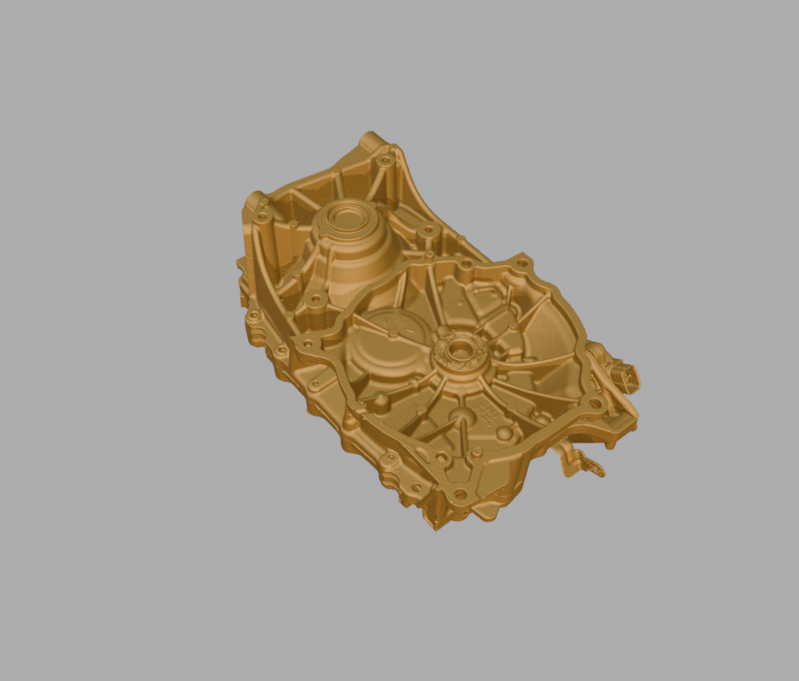

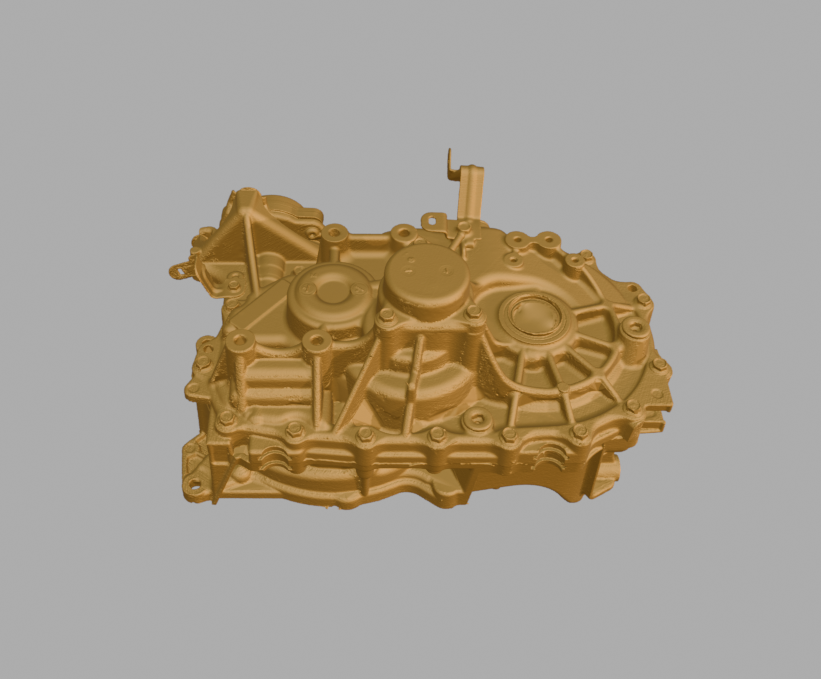

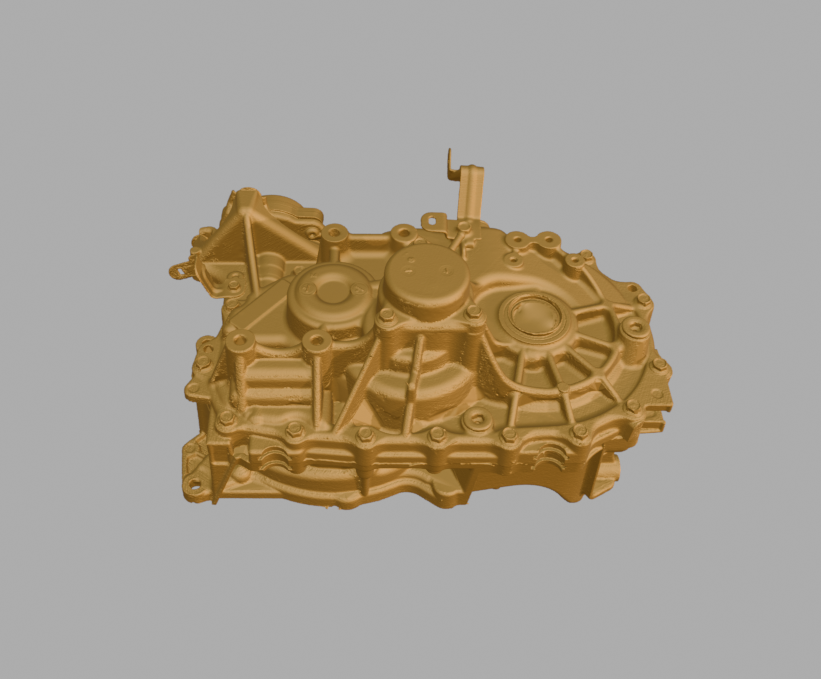

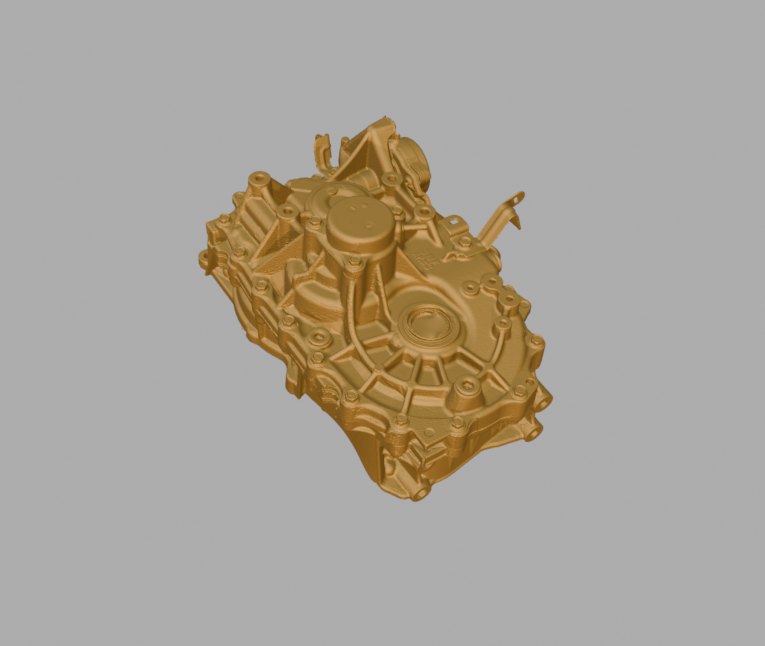

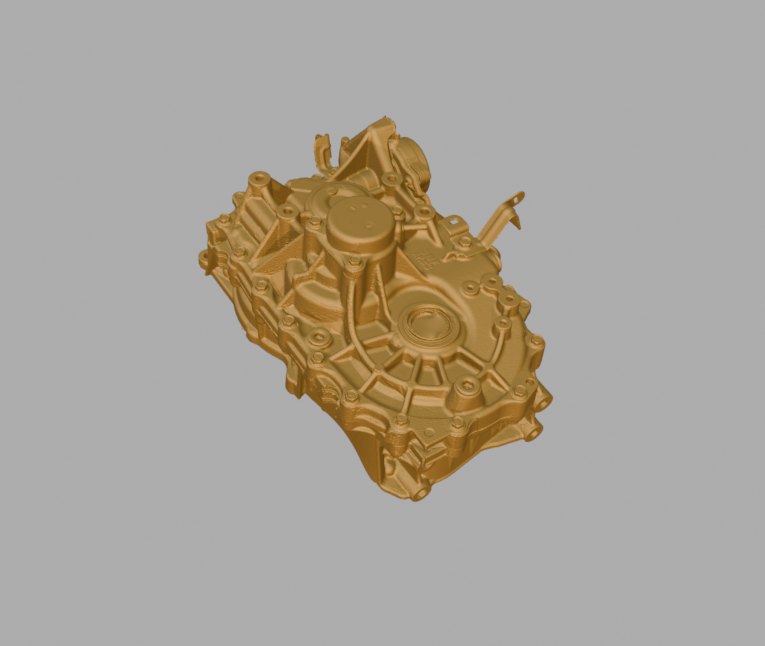

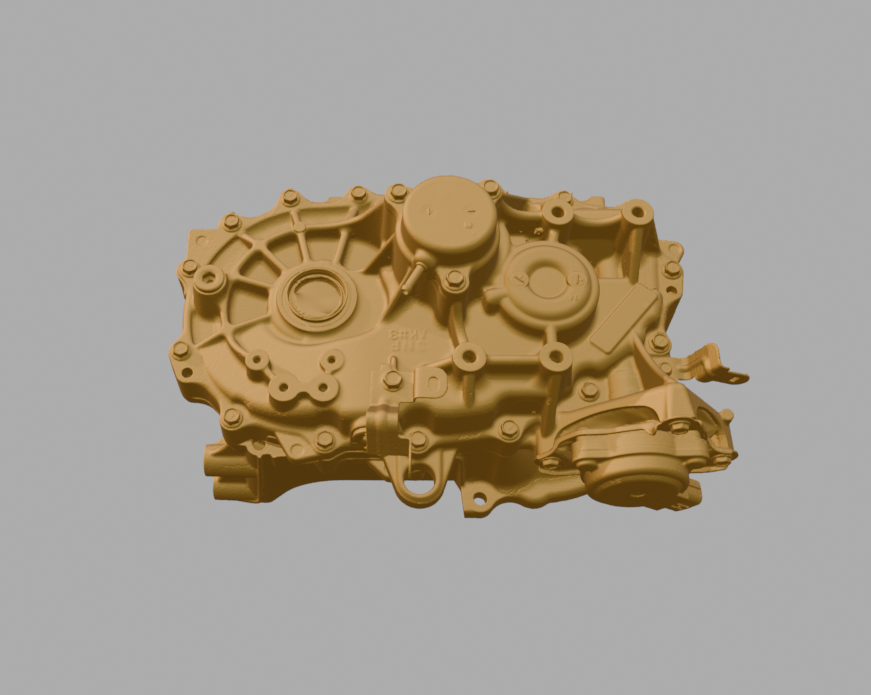

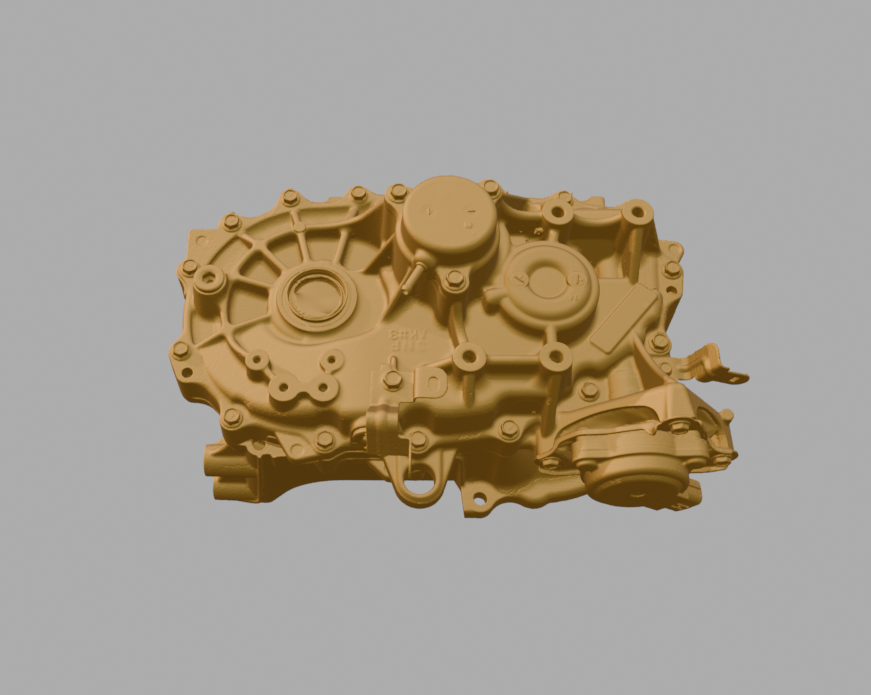

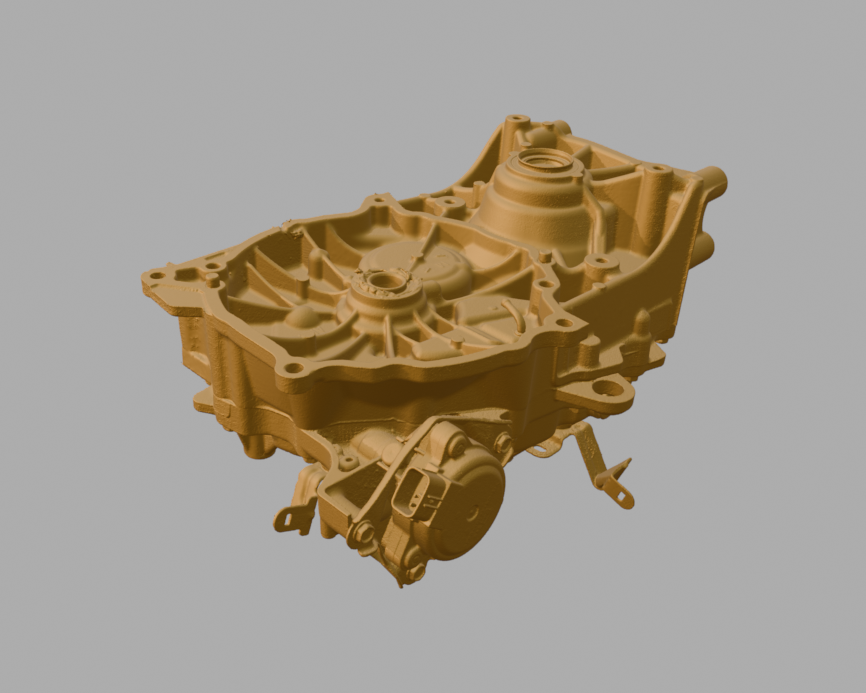

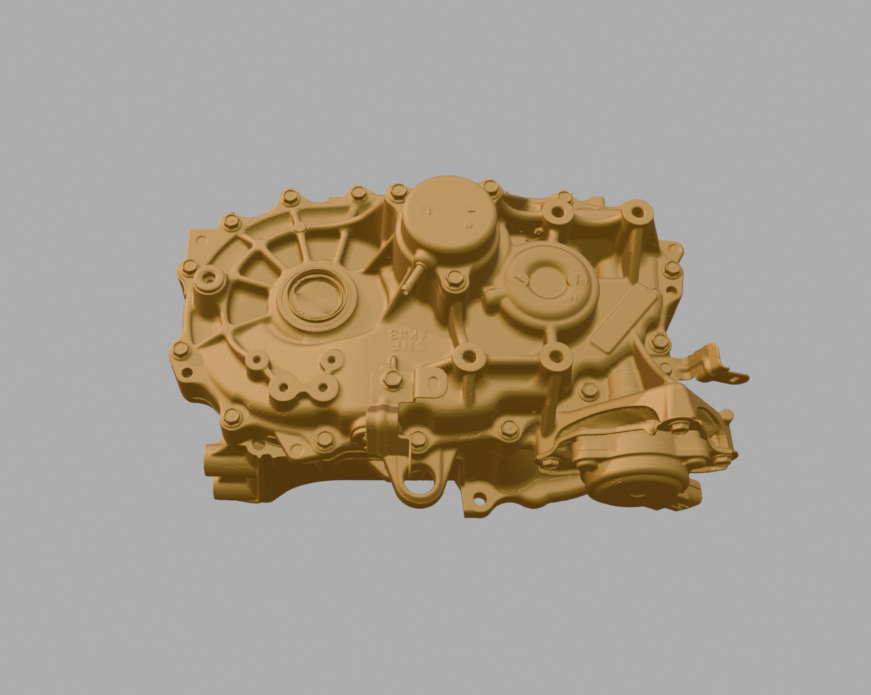

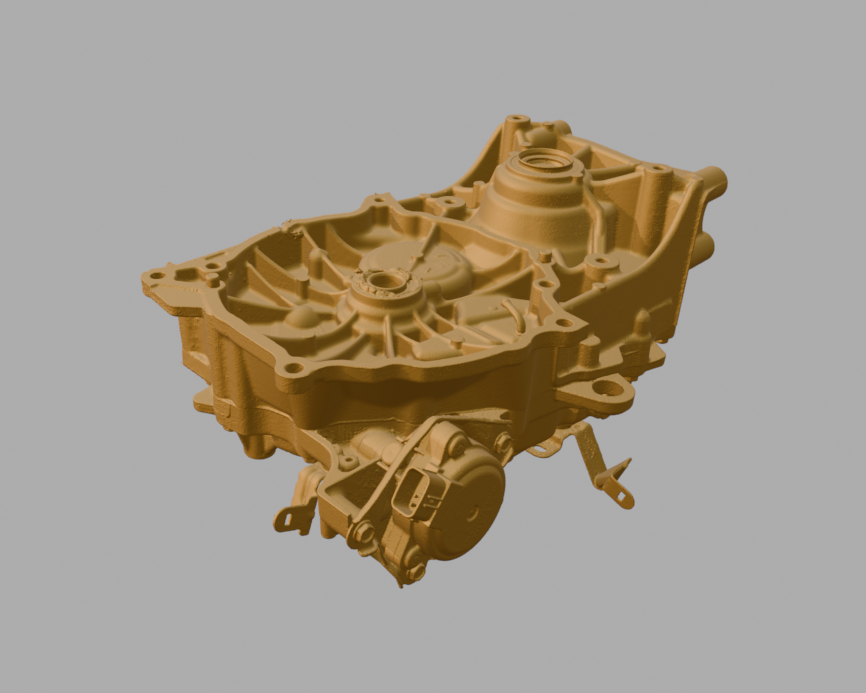

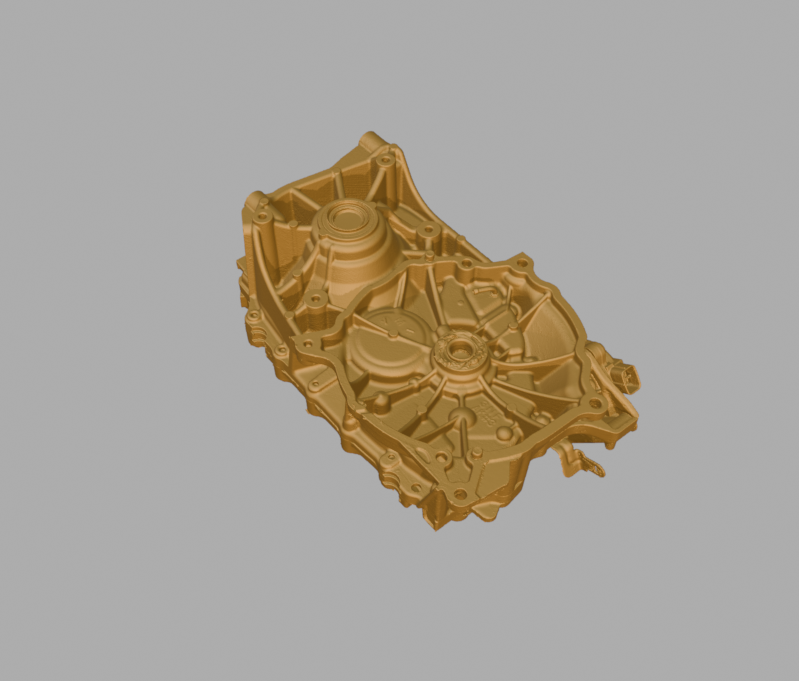

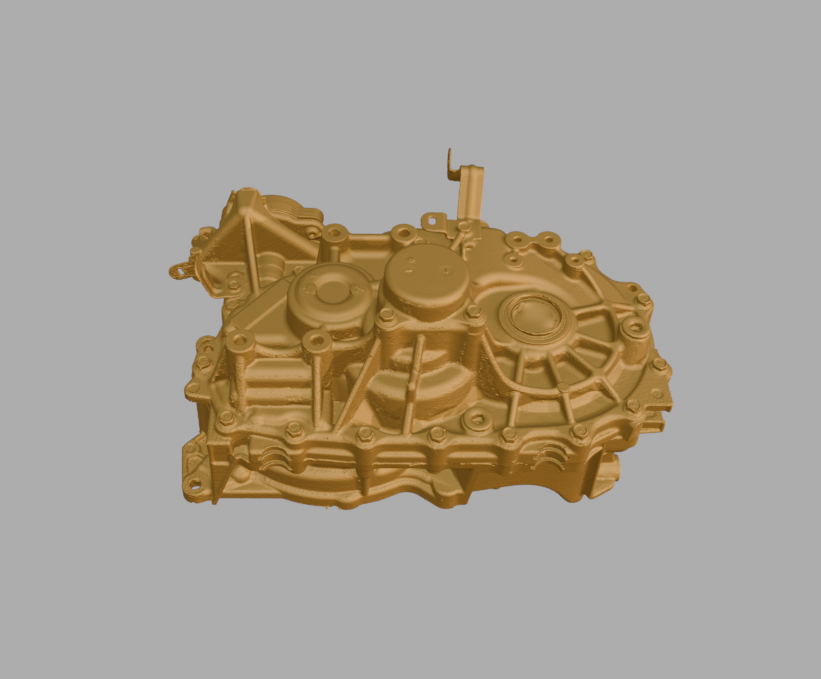

Nissan Leaf EM57 Gearbox - 3D Scan (STL) [Item: PIV]

Contributor: emerald_sovienok

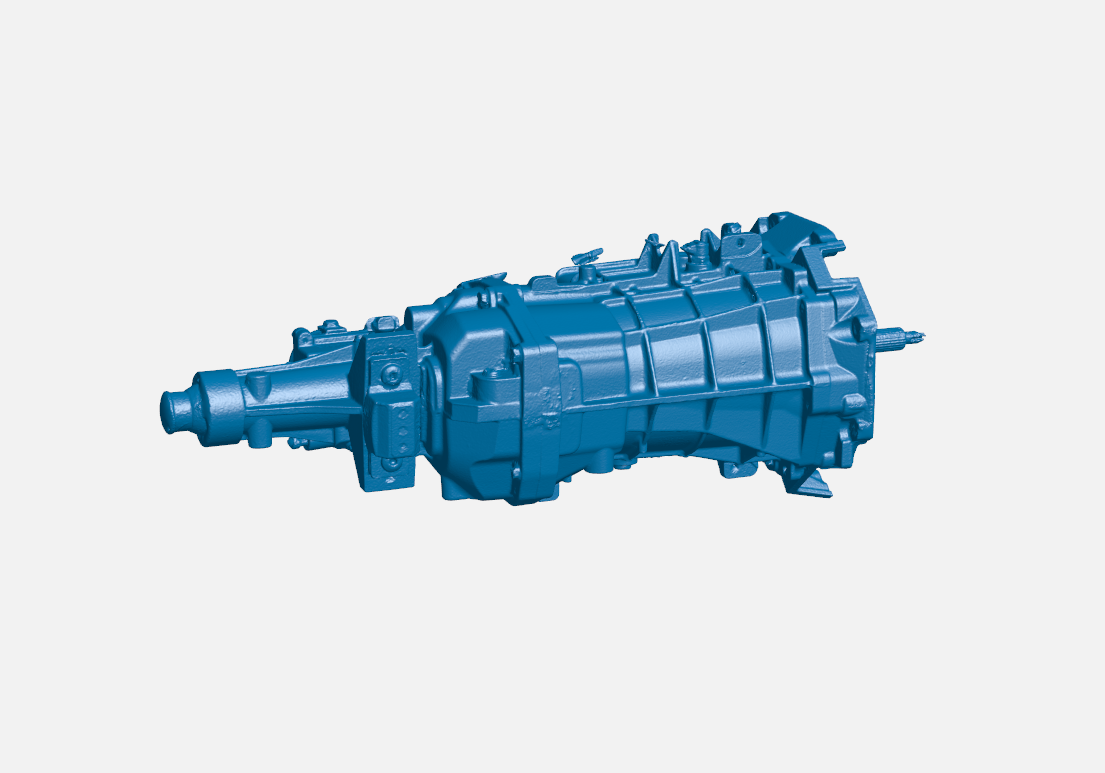

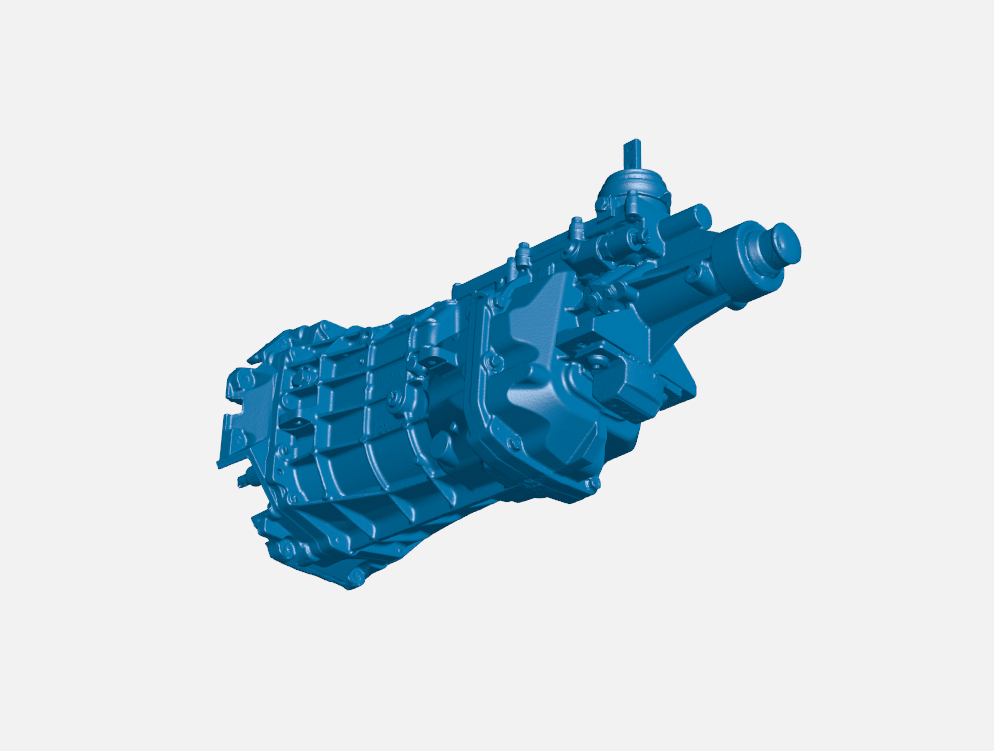

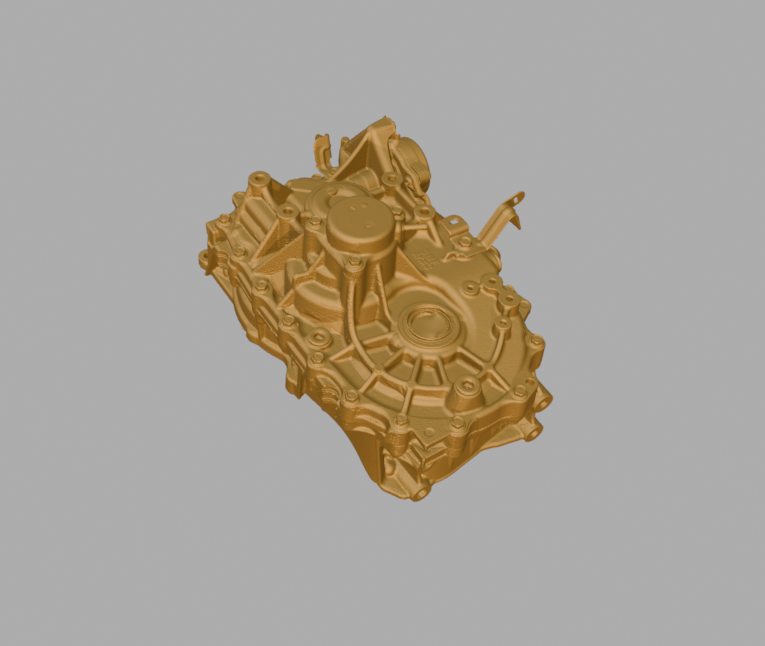

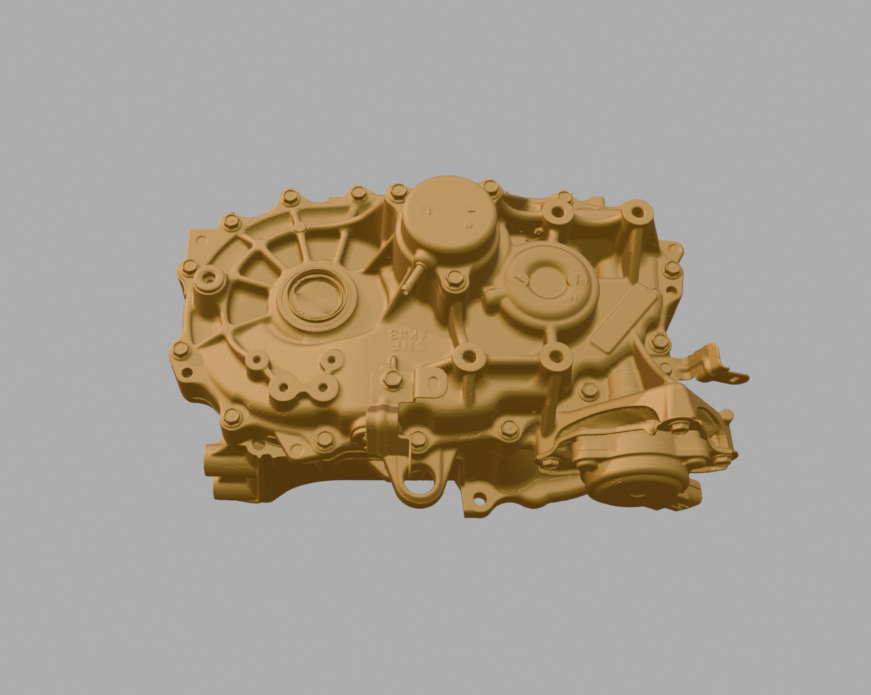

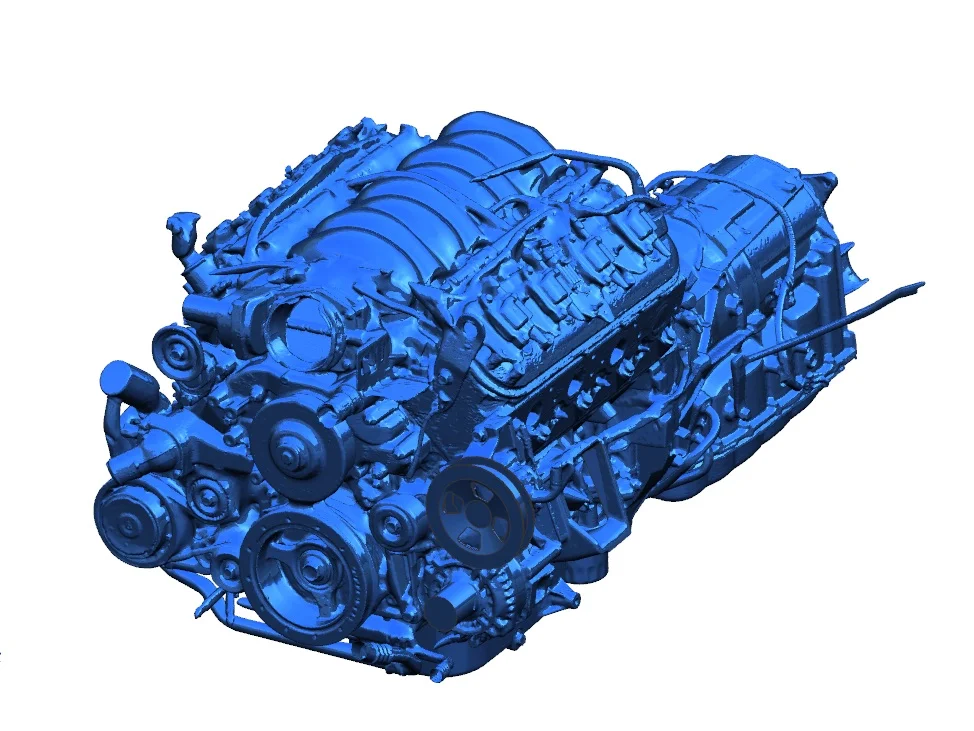

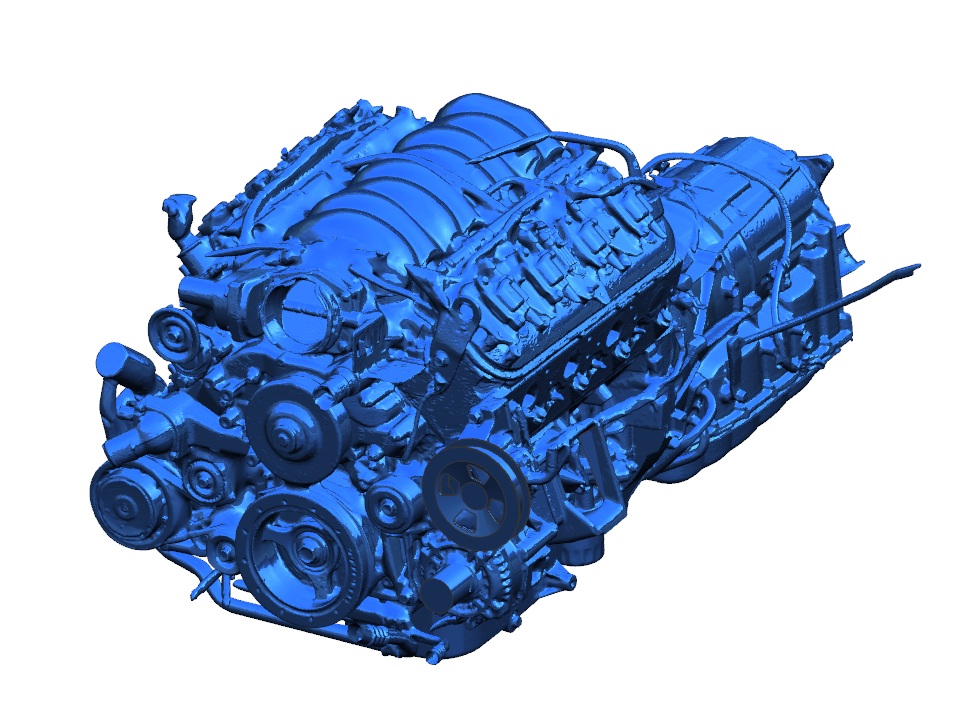

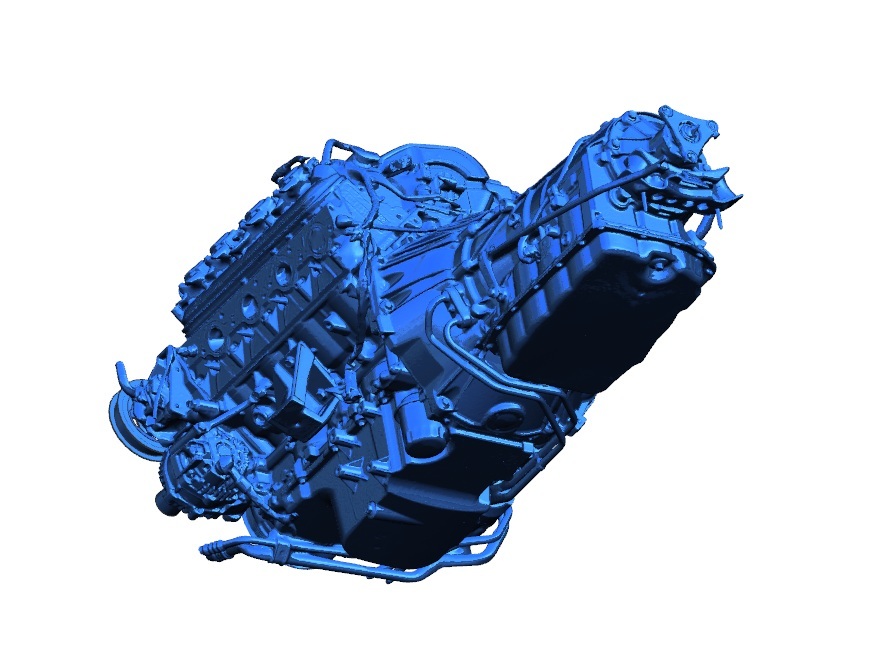

This listing provides a high-resolution 3D scan of the Nissan Leaf EM57 reduction gearbox housing, which transfers and reduces motor output speed before delivering torque to the driveshafts. The gearbox plays a critical role in drivetrain packaging, mounting alignment, and torque transmission within EV conversion and electric motorsport builds.

Scan is compatible with second gen Nissan Leaf (ZE1) 2018-Present.

The scan captures accurate external housing geometry, mounting features, and drivetrain interface locations, supporting custom drivetrain integration and adapter design.

Resolution

3.8M Polygons

Common Applications

EV conversion drivetrain packaging

Custom adapter plate and coupling design

Drivetrain alignment and integration studies

Chassis clearance and fitment validation

Subframe and mounting bracket development

Reverse engineering aftermarket components

Why Use Scan Data?

Electric drivetrain gearboxes often have complex mounting geometry that is difficult to measure accurately using manual methods. Scan data provides real-world dimensional accuracy, allowing digital validation before fabrication.

Scan Coverage

External gearbox housing geometry

Mounting surfaces and bolt interfaces

Drivetrain packaging envelope

Driveshaft interface locations

(Internal gearsets and internal components are not included.)

File Suitability

Ideal for CAD reference, drivetrain packaging, and engineering integration workflows.

Disclaimer:

We encourage you to download the sample file to assess scan format, output quality, and how it performs in your preferred software. Different packages may interpret scan data differently, so verifying compatibility with your workflow is essential.

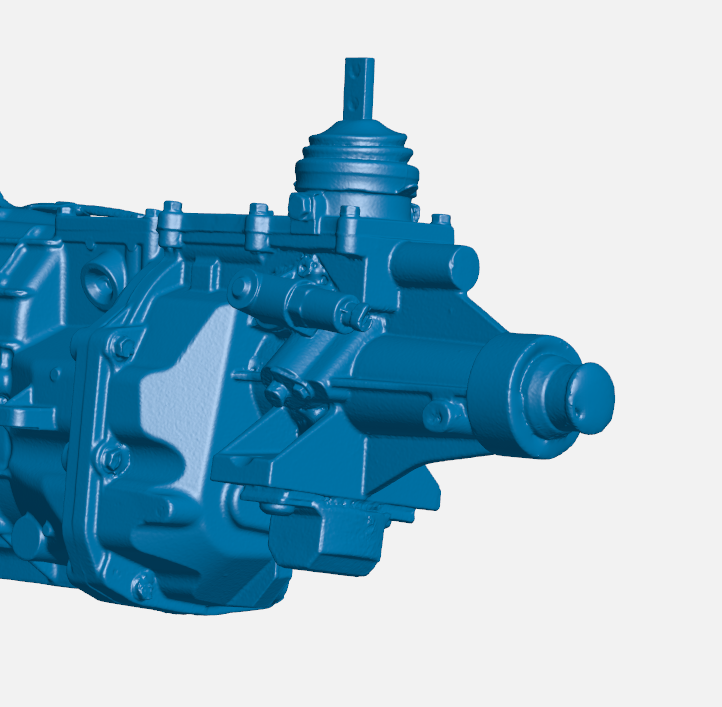

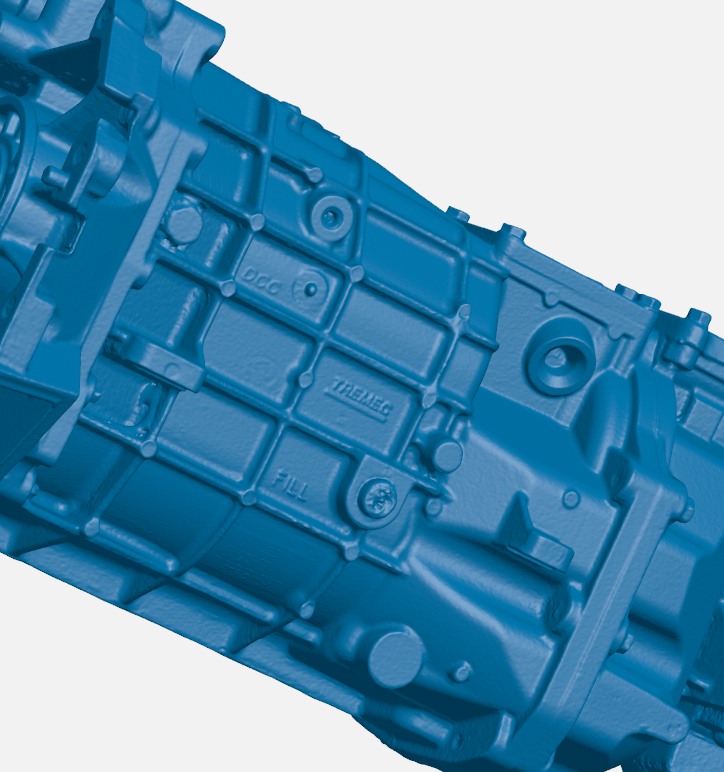

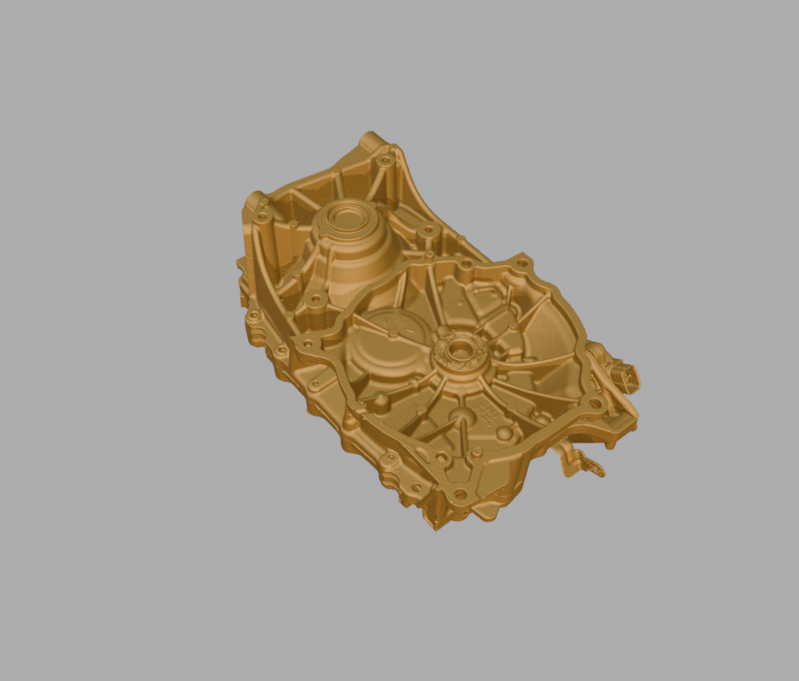

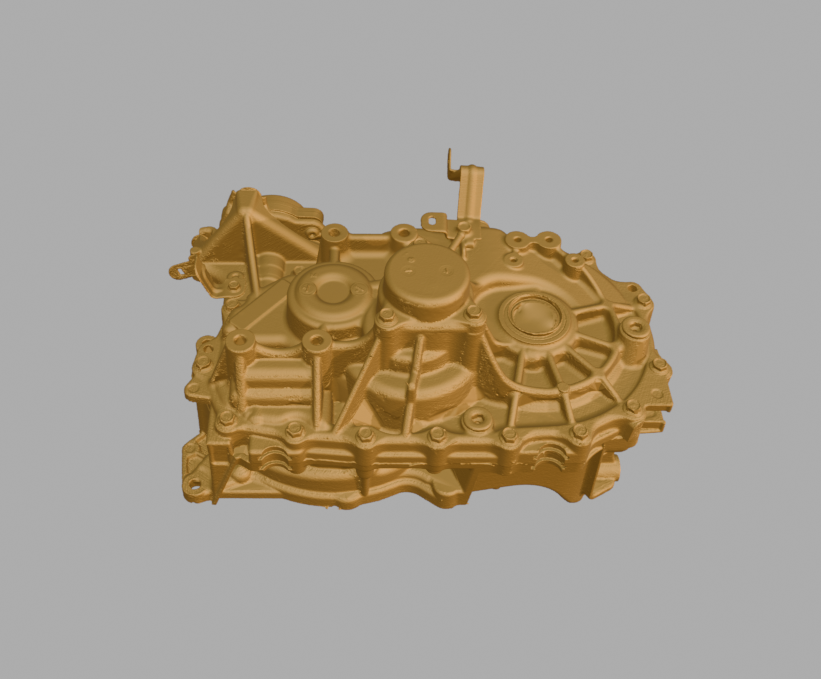

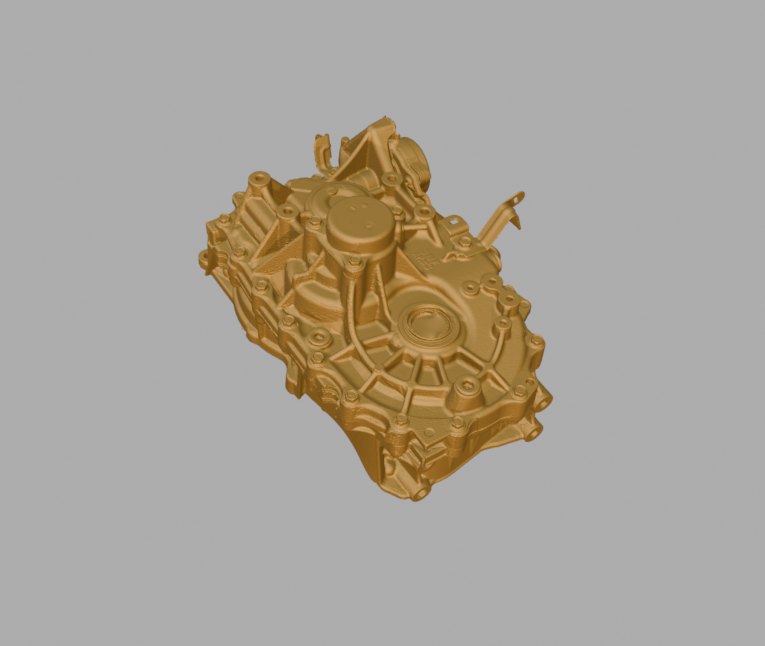

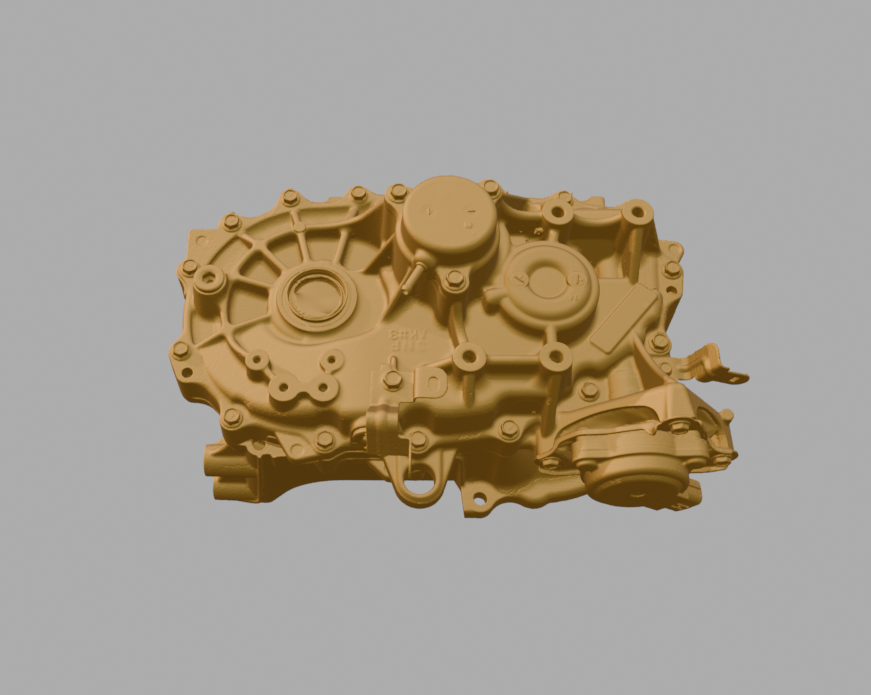

Please refer to the provided part images to evaluate file quality and representation.

While every effort is made during scanning to ensure accuracy, we advise verifying critical dimensions against the physical part if your application requires tight tolerances or precise referencing.

Reviewing both the sample file and images will help ensure the scan meets your requirements before purchase.

Contributor: emerald_sovienok

This listing provides a high-resolution 3D scan of the Nissan Leaf EM57 reduction gearbox housing, which transfers and reduces motor output speed before delivering torque to the driveshafts. The gearbox plays a critical role in drivetrain packaging, mounting alignment, and torque transmission within EV conversion and electric motorsport builds.

Scan is compatible with second gen Nissan Leaf (ZE1) 2018-Present.

The scan captures accurate external housing geometry, mounting features, and drivetrain interface locations, supporting custom drivetrain integration and adapter design.

Resolution

3.8M Polygons

Common Applications

EV conversion drivetrain packaging

Custom adapter plate and coupling design

Drivetrain alignment and integration studies

Chassis clearance and fitment validation

Subframe and mounting bracket development

Reverse engineering aftermarket components

Why Use Scan Data?

Electric drivetrain gearboxes often have complex mounting geometry that is difficult to measure accurately using manual methods. Scan data provides real-world dimensional accuracy, allowing digital validation before fabrication.

Scan Coverage

External gearbox housing geometry

Mounting surfaces and bolt interfaces

Drivetrain packaging envelope

Driveshaft interface locations

(Internal gearsets and internal components are not included.)

File Suitability

Ideal for CAD reference, drivetrain packaging, and engineering integration workflows.

Disclaimer:

We encourage you to download the sample file to assess scan format, output quality, and how it performs in your preferred software. Different packages may interpret scan data differently, so verifying compatibility with your workflow is essential.

Please refer to the provided part images to evaluate file quality and representation.

While every effort is made during scanning to ensure accuracy, we advise verifying critical dimensions against the physical part if your application requires tight tolerances or precise referencing.

Reviewing both the sample file and images will help ensure the scan meets your requirements before purchase.

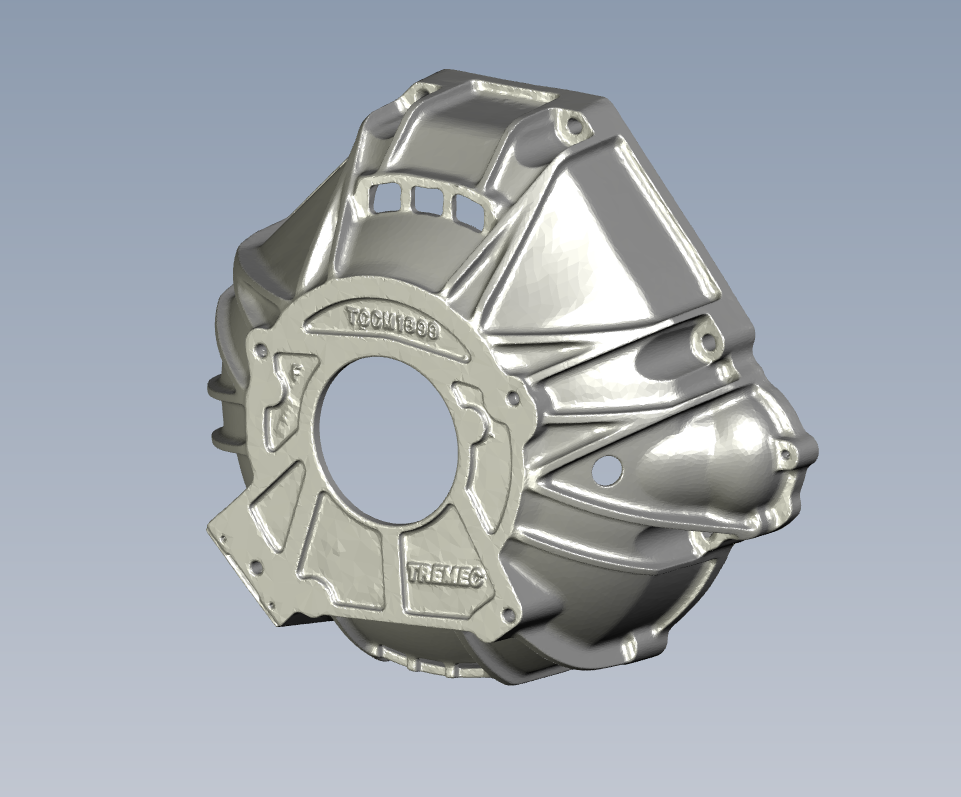

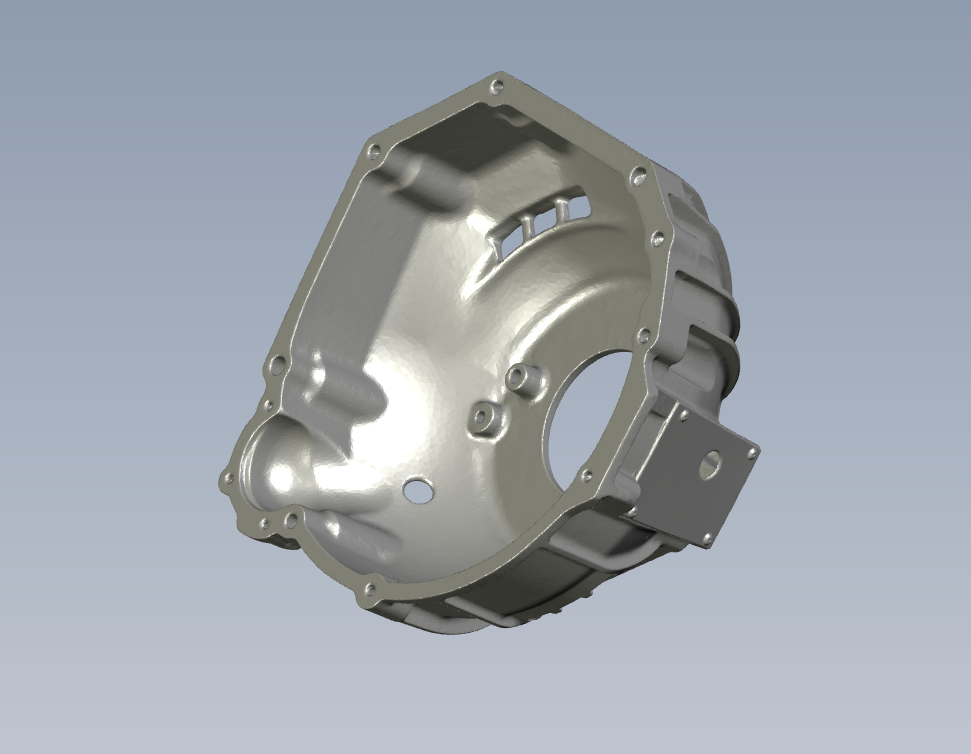

![Chevrolet T56 Magnum - 3D Scan (STL) [Item: GAL]](https://images.squarespace-cdn.com/content/v1/5aaee99b96e76f27dc94b28a/2b4f2e60-4800-4fba-847f-e5d141a75d77/Best_STL_Viewer_mjZVF4tVP5.png)